The paintshop maintenance is built on the following three aspects of working in order to guarantee a clean and qualified environment for keeping painting quality and improving painting one-pass-rate.

1. The professional services of cleaning for all key areas in paint shop: following the standardized procedures and operation techniques; using the effective chemicals, materials and cleaning facilities; conducted by the trained and skillful specialists.

2. Monitoring the all related equipments and facilities in the client's paint shops.

3. Assisting client to cope with emergencies and accidents.

The maintenance services include:

1/ Paintshop general/advanced cleaning services

2/ Anti-static jumpsuit service

3/ Paint defect analysis process (PDAP)

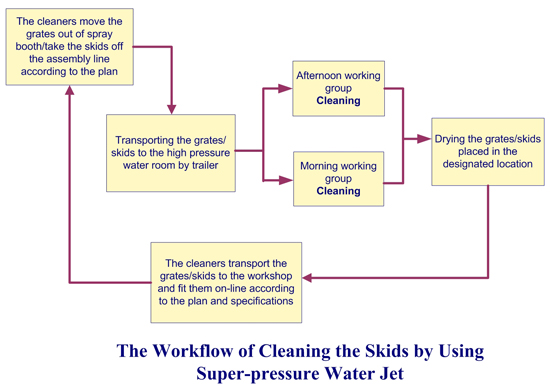

4/ Skid, grid and clamp cleaning service

5/ High-pressure cleaning equipment management

6/ Filter management service

7/ Isolation and anti-corrosion service

8/ Materials receipt in inventory management

9/ Staff management service

Paintshop general/advanced cleaning services

The paintshop general cleaning service is a regular cleaning service including shop floor, glasses, walls and other needed cleaning. Shanghai Haas strictly follows the SOS in operation, controls the service quality through track sheet of visual assessment, trains every worker before they begin operating, and strives to minimize the impact of the trained operator to paint quality.

The advanced cleaning service applies to skids, grids, clamps, hoists, paint mixing rooms, spray booths, drying rooms, bar magnets and heat exchangers etc. Shanghai Haas imports PDCA model in maintenance, planning, doing and checking, acting until the whole process haas been standardized. To guarantee the high quality of cleaning and its measurability, each cleaning job or specific working is assigned and managed strictly in accordance with SOS.

Anti-static jumpsuit service

In an airtight environment with the filtered air, the worker's anti-static jumpsuit often is an unignorable foreign factor of pollution sources. Controling the amount of dust on jumpsuit means to controlling a pollution source. Therefore, enhancing the management of jumpsuit can correspondingly reduce the negative impacts on the quality of painting coating.

Shanghai Haas provides a centralized and unified management from jumpsuit collecting, cleaning, patching to dispatching to meet the standards of different kinds of paintshops. The abluent used for jumpsuit is Haas-made environment-friendly chemical that can guarantee the wearer's health and top cleanliness of jumpsuit.

The services provided by Shanghai Haas include filter pressure records; filter replacement; air particle index test; the professional cleaning of air supply-room and other aspects of day to day management.

High-pressure cleaning equipment management

Paint defect analysis process (PDAP)

The environment issue is the most influential factor to the quality of painting coating so that a more refined analysis of paint defect provided by Shanghai Haas is the core service of the Paintshop Maintenance. Through a comprehensive and detailed analysis of car-body defects, each quality index can quickly and objectively provide more discernible information to client. Meanwhile, the analysis also identifies working targets for further cleaning. Then, the two parties can form the clearer common direction of working and find new indicators of coating quality improvement.

Under the guide of ISO9001, HFC has established a set of codes for personnel management and a standard work flow for cleaning operation. In practice, HFC continuously improves this system and process for on-site and other specifications in according to the systematic requirements of total quality control.

Materials receipt in inventory management

The Material Test Sheet must be filled out to start a material receiving process. All materials then must accept the listed rigorous tests before being received:

1. Cratering test;

2. Hidden fibers test;

3. solvent resistance test.

Only the test approved materials can access to the workshop for use.

Isolation and anti-corrosion service

Using Haas self-developed chemicals and agents on the key areas of a paint shop, such as: siding panels, steel beams, the inside of wind tubes etc. in the process of preservative treatment and corrosion prevention can greatly extend the life of the facilities in the paint shop.